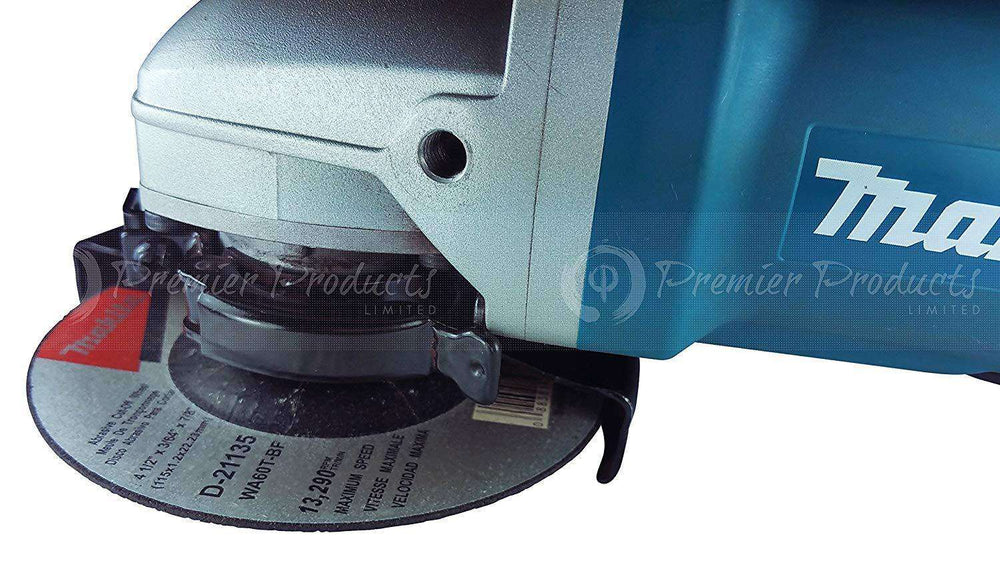

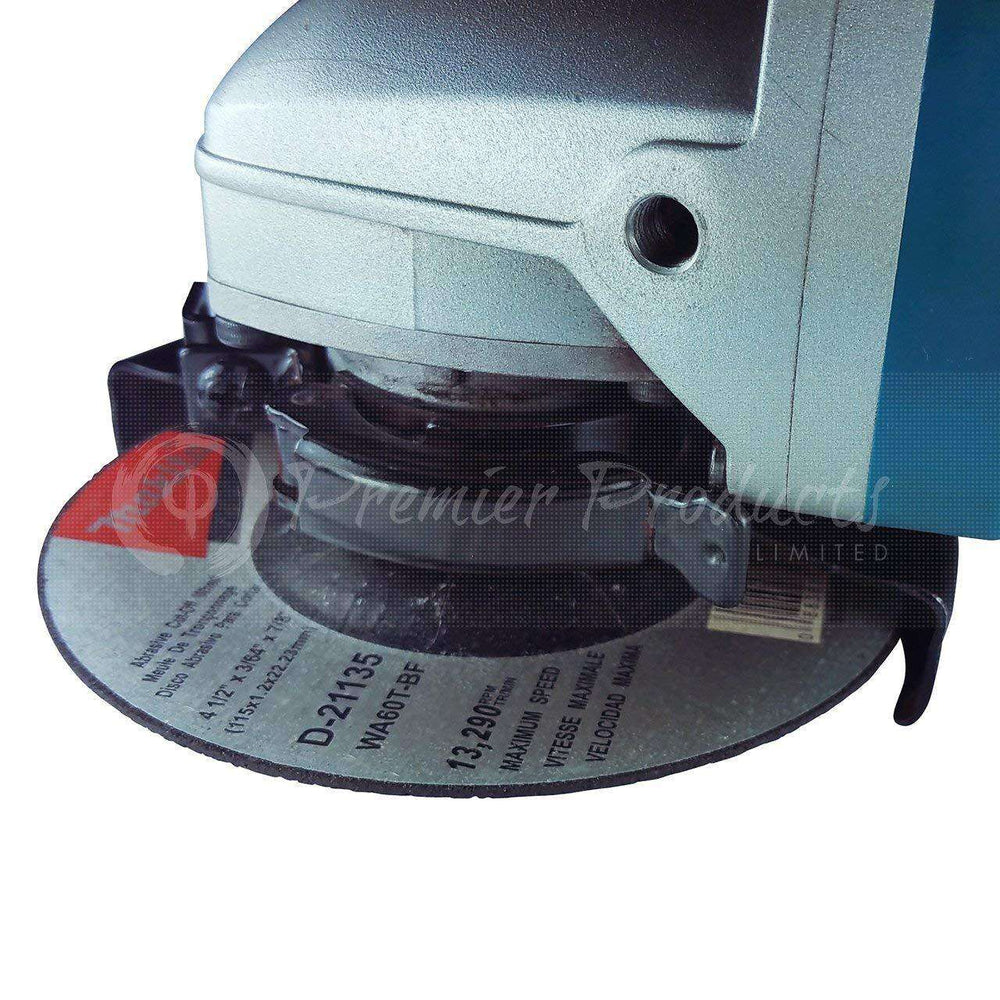

Makita 5 Pack - 4.5" Cut Off Wheels For Grinders - Flush Cutting For Stainless Steel & Metal - 4-1/2" x .045 x 7/8-Inch

✅ 5 MAKITA 4-1/2” Depressed Type 27 Cut Off Wheels for Flush Cuts on Stainless Steel & Metal | 4-1/2-Inch x .045-Inch x 7/8-Inch | Optimized for Makita 4-1/2” Angle Grinders and compatible with All 4-1/2” Angle Grinders with 5/8” arbor

✅ CUT 2-3X More than lower quality or excessively thin wheels due to this wheel’s Carefully selected Grain Grit, Hard Bond Matrix & Wheel Thickness that provide the best balanced Cut Life, Cut Rate, Cut Precision, Power Demands & Heat Buildup in the industry, allowing you to cut longer, consistently precise with unmatched wheel integrity, moderate power demands and relatively low heat buildup

✅ FLUSH CUTS SMOOTHLY, Easily & Quickly through All Stainless Steel & Metal parts including rebar, steel pipe, structural & galvanized steel, sheet metal, structural tubing, black steel, cable and small to medium diameter solid pieces over an extra-long life span due to Makita’s High-performance aluminum oxide grain and proprietary hard bond matrix

✅ AVOID WHEEL SHATTER & Injury with lower priced wheels by relying on Makita’s proprietary strong Synthetic Resinoid Bond matrix that binds Premium White Aluminum Oxide with Phenol Resin, allowing for optimal grain wear which yields accurate cutting PERFORMANCE, PRECISION, LONGEVITY, STABILITY & INTEGRITY, cutting Longer, Faster and Reliably than other wheels that may shatter or prematurely wear

✅ DESIGNED for Hard-to-Reach areas and continuous use on Stainless Steel, these Makita wheels are Quality Assured, Contaminant-Free, containing less than 0.1% Iron, Sulfur or Chlorine, for rust & corrosion-free results for your Stainless Steel material

Engineered for Flush Cuts & Hard-to-Reach areas, these 5 Makita Depressed 4-1/2” Cutting Wheels for Metal & Stainless Steel are a joy to work with. For best results, place wheel at a 90-degree angle, perpendicular to the work surface, applying the proper amount of pressure to allow the cutting wheel to do the work. For best results, consider not pushing too hard on the wheel, which can cause the grinder to stall or kick back or give a less efficient cutting action, while also increasing the chances of slippage or loss of control of the tool, resulting in injury or damage. Applying light to moderate pressure and consistent movement will provide the most efficient cut and minimize heat build-up. Consider using light pressure and a consistent motion throughout the cut for the fastest cut-rate and prolonged wheel life. Excessive pressure through the cut causes increased friction and heat build-up, which can cause increased heat discoloration of the work piece and reduced wheel life. For demanding applications, higher amperage &/or torque angle grinders provide easier, long-lasting & efficient cuts.

Customer Reviews

showing reviews from (% reviewsData.reviews.from %) to (% reviewsData.reviews.to %)

0 Review Posted

Product Questions

0 Question

showing questions from (% questionsData.questions.from %) to (% questionsData.questions.to %)

0 Question Asked