Makita 5 Piece - T Shank Jigsaw Blades For Jigsaws On Wood & PVC

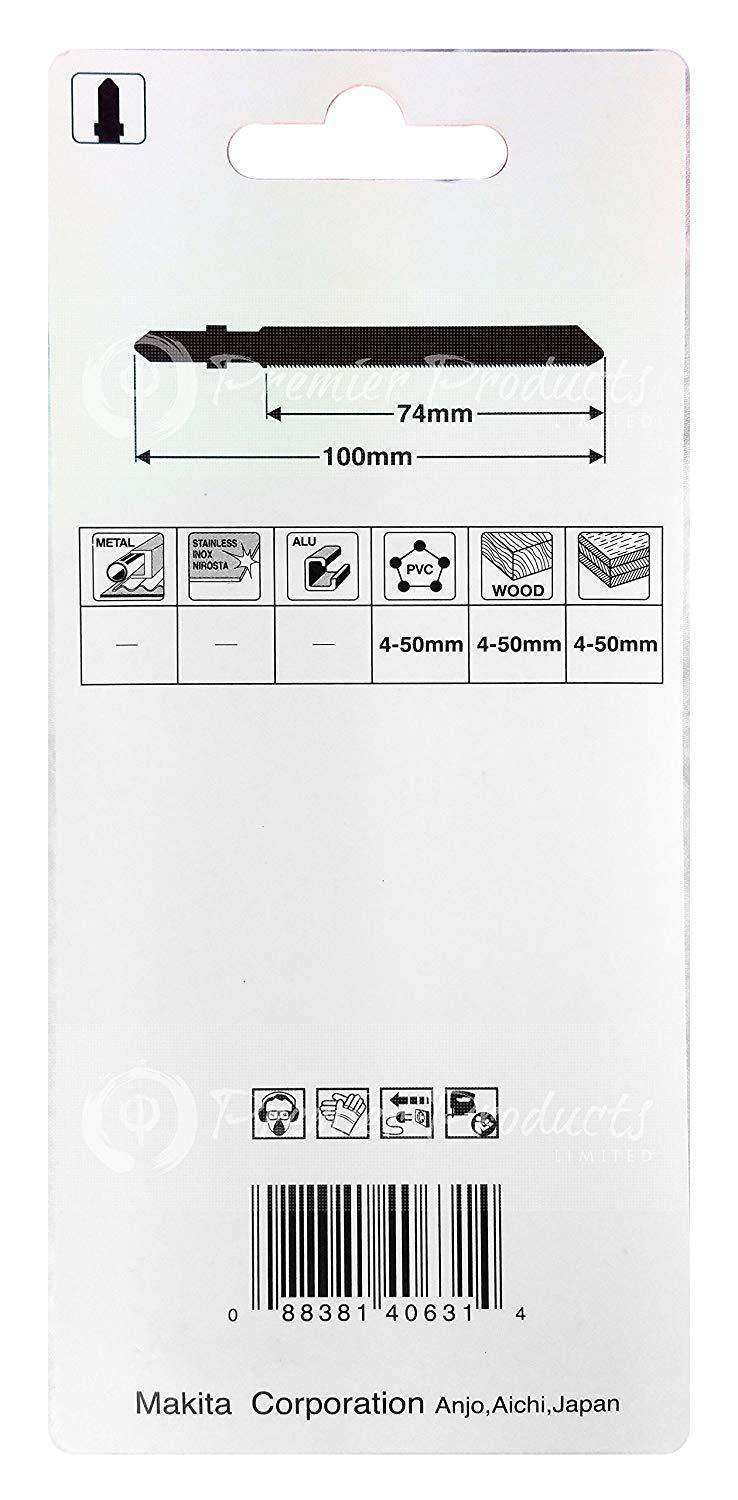

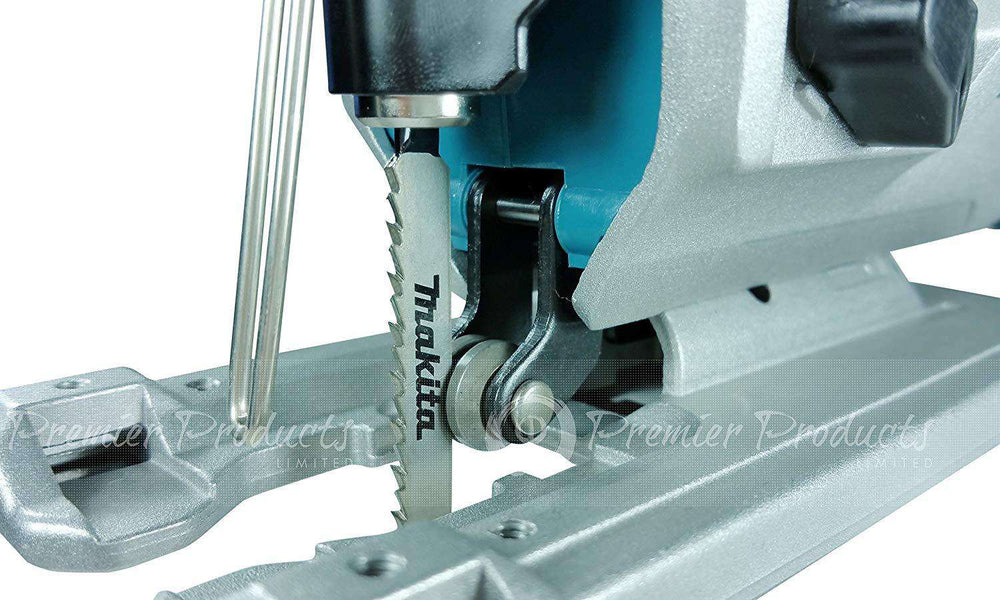

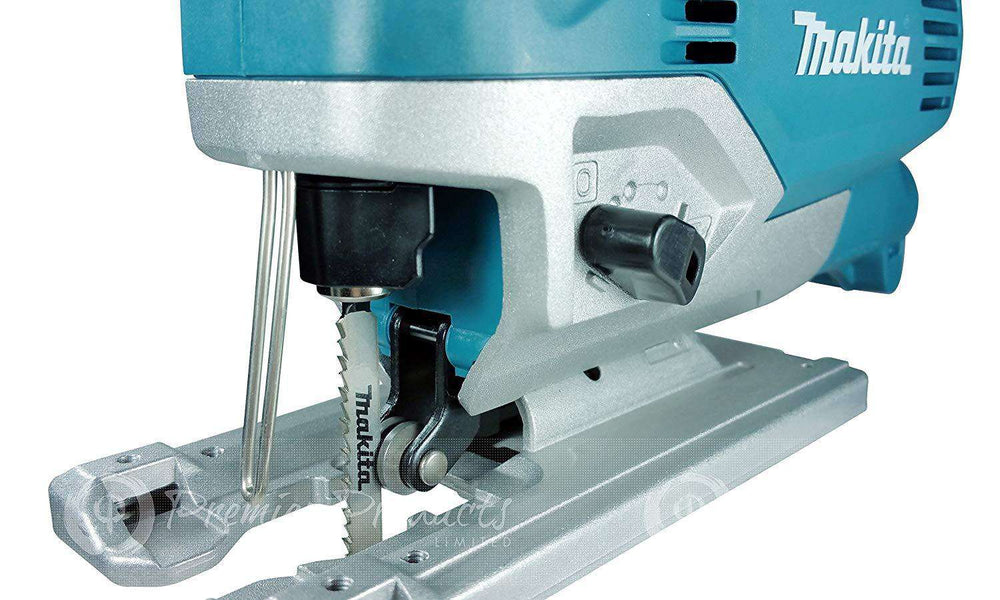

✅ 5 MAKITA BLADES, Fine Straight T-Shank Jigsaw Blade Set with 9 TPI (Teeth Per Inch) blade design for Soft & Engineered Wood and PVC Cutting | Optimized for All Makita T-Shank Jigsaws and compatible with ALL T-Shank Jigsaws

✅ CUT WOOD & PVC CLEANER, MORE ACCURATELY & FINER, without compromising blade or application integrity with Makita’s Exclusive 9 TPI Ground Alternating Teeth Technology

✅ 9 TPI GROUND TEETH & Wide Blade design provide better Straightness Integrity, allowing for Sharper, Straighter, Cleaner Finish and Consistent Cuts after prolonged use, even under the most demanding applications

✅ ENGINEERED with Professional grade, fully hardened, High Carbon Steel (HCS) precision teeth that stay SHARPER longer than competitor blades in its class while Makita's T-Shank design allows for easy blade mount-&-remove, maximal grip and stability

✅ IDEAL for Accurate, Straight & Finer Cut Finishes which is further enhanced by low Jigsaw operating speed and orbital deactivation used by professional carpenters, DIYs, home improvers, electricians, general contractors, roofers, plumbers, frame, drywall & maintenance workers and wood workers on all Soft Wood like cedar, fir, pine and redwood, in addition to Engineered Wood like plywood, laminate, glulam, particle board, fiberboard, oriented strand board, plastic and construction lumber

Makita’s T-Shank Jigsaw blades for Finer Cutting on Soft Wood & PVC are ideal for woodworkers with varied cleaner finish applications. For the most accurate cuts and maximal blade longevity, consider low Jigsaw operating speeds and orbital deactivation while ensuring that the wood is fastened and secured, applying a firm slight forward pressure on the Jigsaw tool and allowing the blade to do the cutting. Softer wood applications enables one to use higher operating speed and orbital action without sacrificing cutting precision, while harder wood & plastic requires slower speeds and no orbital action so as to reduce the risk of jamming, excessive heat buildup and material burning while also ensuring the smoothest finishes. In general, faster, more aggressive orbital action yields a more ragged splintered finish, while slower, non-orbital action yields a finer finish.

Customer Reviews

showing reviews from (% reviewsData.reviews.from %) to (% reviewsData.reviews.to %)

0 Review Posted

Product Questions

0 Question

showing questions from (% questionsData.questions.from %) to (% questionsData.questions.to %)

0 Question Asked